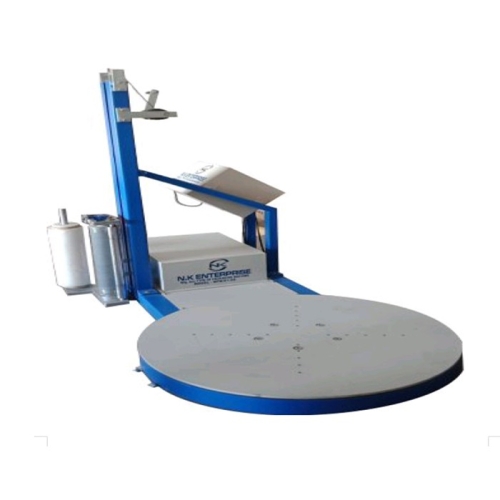

Technical Specification

MODEL :NKP-01-FA. TT 1650

Performance

Turntable speed: 0 to15rpm

Loads per hour: 18 To 20/hr depending upon the pick & place of pallet

Wrapping Height: 2500 mm

MAX. Loading weight: 2000 kg

Mechanical specification

Turntable Diameter: 1650 mm (pallet size : 1200X1200 mm)

Turntable Height: 80 mm

Machine Length (mm): 2650 mm

Machine Width (mm): 1650mm

Machine Height (mm): 2800 mm

Construction: M.S. Sheet , LASER cut machine, Al. Alloy & channel

Structure: MS powder coated

Pallet loading and unloading: Ramp (pallet Loading/Unloading)

Shipping Weight: 850 Kg approx

Film Delivery System

Type: Power pre stretch

Film stretch: 250 To 300% (adjustable)

Film Specification

Film roll OD: 250 To 300 mm

Core size: 75 mm

Film roll height: 20 inch (standard size)

Film thickness (micron): 29 To 50 micron

Electrical Specification

Power requirement: 380/440V , 50Hz ,3 phase + N

Power consumption: 2.25 kw

Controller type: Delta/Siemens make, PLC + HMI with PLC having recipe function will Alloy saving different programmed.

Ac Drive make(VFD): Delta/ Siemens make

Motor: Crompton make

Switchgear: Schneider make

Cable: RR cable make

Sensor: P&F make

Turntable Motor: 2 HP,750W×1440rpm 3-phase, 750V/50Hz AC geared Motor 1:30

Film Elevator motor: 0.5HP, 250W×1440rpm 3 phase, 380V/50Hz AC geared Motor 1:80,

Powered Pre stretch motor: 0.5HP, 250W X1440rpm 3-phase, 380V/50Hz AC geared Motor, 1:10